Professional slip ring manufacturer

power slip ring

”The latest newsThe wire precious metal brush improves the shortcomings of the composite metal brush, with small wear debris, small size, and good signal transmission stability, but the bearing capacity is very limited. Fiber brushes are designed with multiple metal fibers, which maintain multiple points of contact with the metal ring body, and have excellent electrical conductivity and high current density.

What is the service life of the conductive slip ring? How long is the service life of the conductive slip ring? In fact, the life of the conductive slip ring depends on many factors, which can be roughly divided into two categories. One is the service life of the material used for the slip ring itself. This is a question that many clients often ask me, and today we will discuss it.

Slip rings can be divided into carbon brush slip rings and electric brush slip rings according to their internal structure and application fields. The carbon brush slip ring was born relatively early, and the carbon brush and the copper ring are used to contact the inside. The working principle is that the carbon brush holder contacts the slip ring, the stator does not move, and the rotor rotates to realize 360-degree rotation.

The conductive slip ring is a method for connecting 360 degree rotators, transferring energy and signals, which solves the problem of gas electricity mixing in the rotating part. With the further implementation of China's new energy policy and emission reduction policy, as well as the strong support and implementation of the country for the wind power industry, small wind power conductive slip rings have been increasingly used in the wind power industry.,

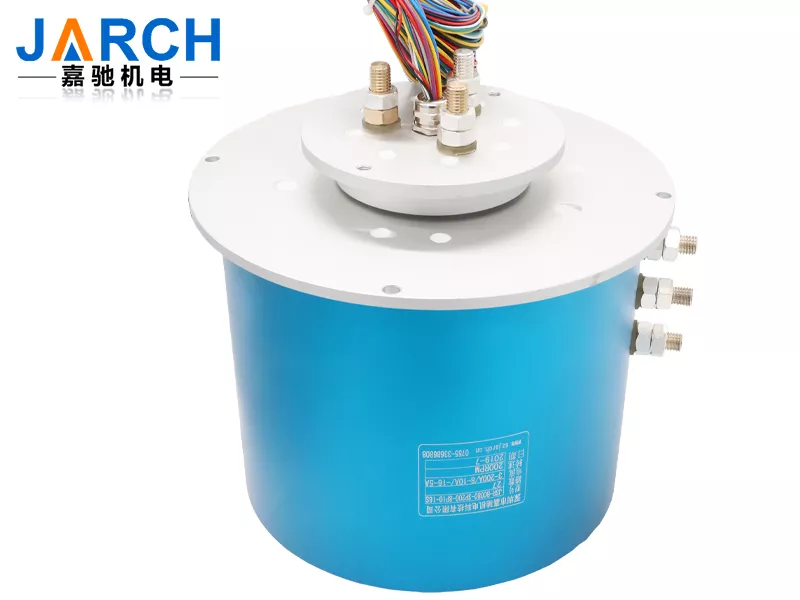

The conductive slip ring usually refers to the conductive slip ring with a single current of more than 50A. Because the current transmitted by this type of conductive slip ring is too large, it is different from the conventional conductive slip ring in many places. Because the transmission device is a large current conductive device, the contact between the contact material and the brush should be considered first to ensure the reliability and life of the large current conductive ring contact.

Wind power slip ring exhibition

China's wind power industry is moving from a stage of rapid growth to a stage of sustainable and healthy development. At this stage, the fan industry needs more safe, reliable and reliable rotating electrical connection technology, and these are the expertise of Jiachi. We also have excellent technical capabilities to simplify installation procedures and troubleshoot potential failures for our customers. At this exhibition, we are presenting the latest technologies and innovative solutions capable of meeting both onshore and offshore wind power applications.

news

- New HD High Frequency Video Combination Slip Ring Solution!!!Why does High-end Equipment Use Fiber Optic Slip Rings Instead of Standard Slip Rings? How Wide the Application Range of Mercury Slip Rings,Do You Know it?

- How to solve the problem of smoke when the conductive slip ring is in use?---The importance of using fiber brush technology for conductive slip ring,and do you know the Wind power slip ring?

- How to Choose the Model of the Slip Ring You Need? The Installation Method of the Rotating Slip Ring--Shaft or Flange?

- The difference between the old carbon brush slip ring and the new brush slip ring, what are the media transmitted by the slip ring?

- How to use disc conductive slip rings and the advantages and characteristics of mercury slip rings

- How does the slip ring realize the simultaneous transmission of multiple media? How does a slip ring work?

- Is the life of the conductive slip ring long? Why is the service life of the mercury slip ring not long?

- Is it true that miniature cap-type slip rings are widely used in anchor fish equipment? How to choose a through hole slip ring correctly?